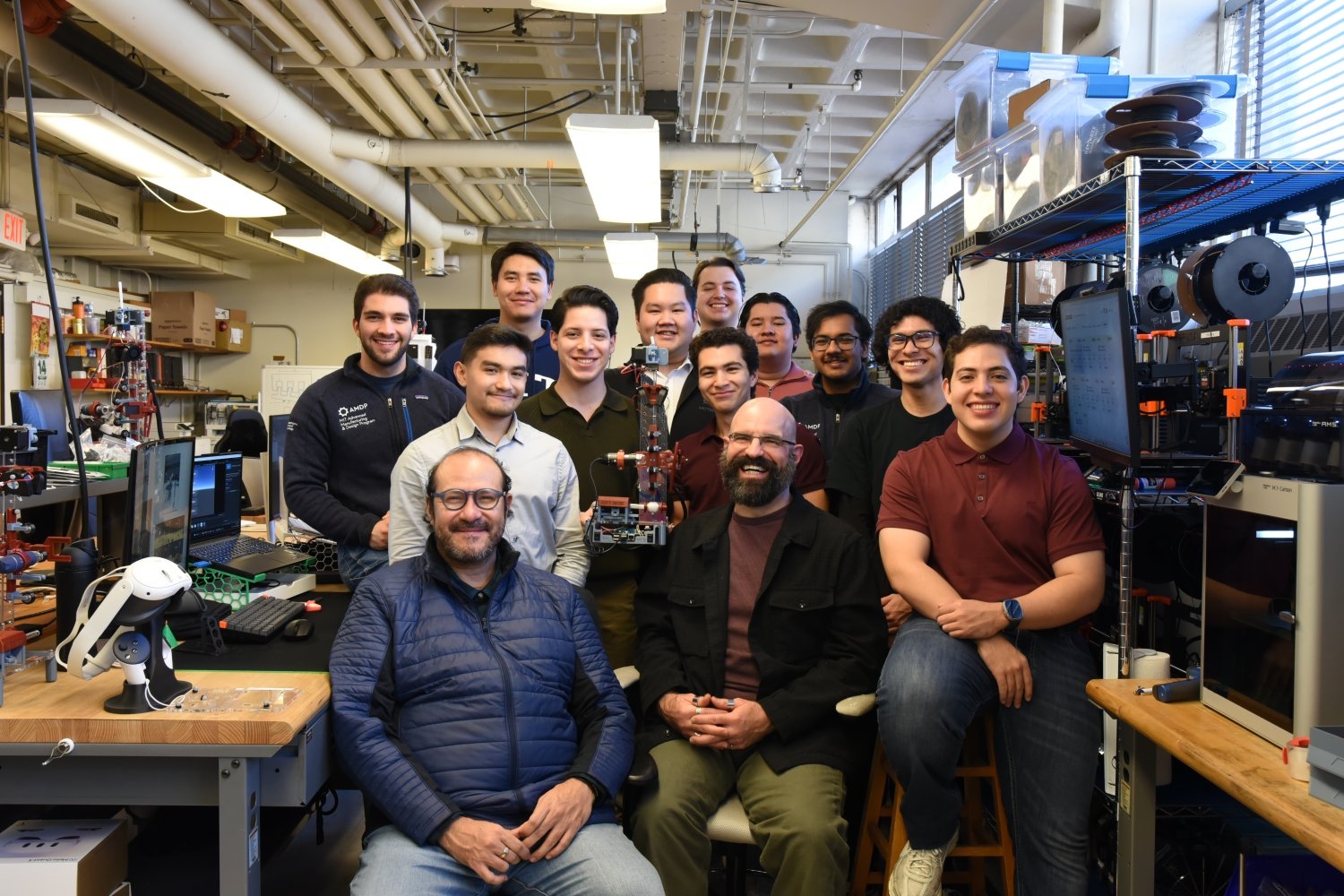

For over a decade, by way of a collaboration managed by MIT.nano, MIT and Tecnológico de Monterrey (Tec), one of many largest universities in Latin America, have labored collectively to develop progressive tutorial and analysis initiatives with a specific focus in nanoscience and nanotechnology and, extra just lately, an emphasis on design and sensible manufacturing. Now, the collaboration has additionally expanded to incorporate undergraduate schooling. Seven Tec undergrads are growing strategies to fabricate low-cost, desktop fiber-extrusion gadgets, or FrEDs, alongside friends at MIT in an “in-the-lab” educating and studying manufacturing unit, the FrED Manufacturing facility.

“The FrED Manufacturing facility serves as a factory-like schooling platform for manufacturing scale-up, enabling college students and researchers to interact firsthand within the transition from prototype improvement to small-scale manufacturing,” says Brian Anthony, MIT.nano affiliate director and principal analysis scientist within the MIT Division of Mechanical Engineering (MechE).

By means of on-campus studying, individuals observe, analyze, and actively contribute to this course of, gaining important insights into the complexities of scaling manufacturing operations. The product of the FrED Manufacturing facility are FrED kits — tabletop manufacturing kits that themselves produce fiber and which are used to show sensible manufacturing ideas. “We’re thrilled to have college students from Monterrey Tec right here at MIT, bringing new concepts and views, and serving to to develop these new methods to show manufacturing at each MIT and Tec,” says Anthony.

The FrED manufacturing unit was initially constructed by a gaggle of MIT graduate college students in 2022 as their thesis mission within the Grasp of Engineering in Superior Manufacturing and Design program. They tailored and scaled the unique design of the machine, constructed by Anthony’s scholar David Kim, into one thing that may very well be manufactured into a number of items at a considerably decrease price. The ensuing computer-aided design recordsdata have been shared with Tec de Monterrey to be used by college and college students. Since launching the FrED curriculum at Tec in 2022, MIT has co-hosted two programs led by Tec college: “Mechatronics Design: (Re) Design of FrED,” and “Automation of Manufacturing Methods: FrED Manufacturing facility Problem.”

New this tutorial yr, undergraduate Tec college students are taking part in FrED Manufacturing facility analysis immersions. The scholars interact in collaborative FrED tasks at MIT after which return to Tec to implement their data — notably to assist replicate and implement what they’ve realized, with the launch of a brand new FrED Manufacturing facility at Tec de Monterrey this spring. The tip purpose is to completely combine this mission into Tec’s mechatronics engineering curriculum, during which college students find out about automation and robotics firsthand by way of the gadgets.

Russel Bradley, a PhD scholar in MechE supervised by Anthony, is the mission lead of FrED Manufacturing facility and has been working carefully with the undergraduate Tec college students.

“The method of designing and manufacturing FrEDs is an academic expertise in itself,” says Bradley. “In contrast to an actual manufacturing unit, which probably wouldn’t welcome college students to experiment with the machines, the FrED manufacturing unit gives an setting the place you may fail and study.”

The Tec undergrads are divided into teams engaged on particular tasks, together with Improvement of an Training 4.0 Framework for FrED, Immersive Expertise (AR) for Manufacturing Operations, Gamifying Superior Manufacturing Training in FrED Manufacturing facility, and Immersive Cognitive Manufacturing facility Twins.

Sergio Siller Lobo is a Tec scholar who’s engaged on the event of the schooling framework for FrED. He and different college students are revising the code to make the interface extra student-friendly and greatest allow the scholars to study whereas working with the gadgets. They’re centered notably on serving to college students to interact with the subjects of management methods, laptop imaginative and prescient, and web of issues (IoT) in each a digital course that they’re growing, and in immediately working with the gadgets. The digital course could be introduced by an teacher or accomplished autonomously by college students.

“College students could be studying the speculation with the digital programs, in addition to gaining access to hands-on, sensible expertise with the machine,” says Siller Lobo. “You may have one of the best of each methods of studying, each the sensible and the theoretical.”

Arik Gómez Horita, an undergrad from Tec who has additionally been engaged on the schooling framework, says that the expertise that presently exists when it comes to how one can educate college students about management methods, laptop imaginative and prescient, and IoT is usually very restricted in both its functionality or amount.

“A key side of the worth of the FrEDs is that we’re integrating all these ideas and a module for schooling right into a single machine,” says Gómez Horita. “Bringing FrED right into a classroom is a game-changer. Our most important purpose is attempting to place FrED into the fingers of the instructor, to make use of it for all its educating capabilities.”

As soon as the scholars return to Tec de Monterrey with the academic modules they’ve developed, there might be workshops with the FrEDs and alternatives for Tec college students to make use of their very own creativity and iterate on the gadgets.

“The FrED is mostly a lab in a field, and the most effective issues that FrEDs do is create information,” says Siller Lobo. “Discovering new methods to get information from FrED offers it extra worth.”

Tec college students Ángel Alarcón and André Mendoza are making ready to have MIT college students take a look at the FrED manufacturing unit, working a simulation with the 2 most important roles of engineer and operator. The operator position assembles the FrEDs inside the workstations that simulate a manufacturing unit. The engineer position analyzes the info created on the manufacturing unit aspect by the operator and tries to search out methods to enhance manufacturing.

“It is a very immersive solution to educate manufacturing methods,” says Alarcón. “Many college students finding out manufacturing, undergraduate and even graduate, end their schooling by no means having even gone to an precise manufacturing unit. The FrED Manufacturing facility offers college students the dear alternative to get to know what a manufacturing unit is like and expertise an trade setting with out having to go off campus.”

The information gained from the workstations — together with cycle time and defects in an operation — might be used to show completely different subjects about manufacturing. Finally, the FrED manufacturing unit at Tec might be used to check the advantages and disadvantages of automation versus guide labor.

Bradley says that the Tec college students carry a powerful mechatronics background that provides a whole lot of vital insights to the mission, and past the lab, it’s additionally a useful multicultural trade.

“It’s not nearly what the scholars are studying from us,” says Bradley, “but it surely’s actually a collaborative course of during which we’re all complementing one another.”

For over a decade, by way of a collaboration managed by MIT.nano, MIT and Tecnológico de Monterrey (Tec), one of many largest universities in Latin America, have labored collectively to develop progressive tutorial and analysis initiatives with a specific focus in nanoscience and nanotechnology and, extra just lately, an emphasis on design and sensible manufacturing. Now, the collaboration has additionally expanded to incorporate undergraduate schooling. Seven Tec undergrads are growing strategies to fabricate low-cost, desktop fiber-extrusion gadgets, or FrEDs, alongside friends at MIT in an “in-the-lab” educating and studying manufacturing unit, the FrED Manufacturing facility.

“The FrED Manufacturing facility serves as a factory-like schooling platform for manufacturing scale-up, enabling college students and researchers to interact firsthand within the transition from prototype improvement to small-scale manufacturing,” says Brian Anthony, MIT.nano affiliate director and principal analysis scientist within the MIT Division of Mechanical Engineering (MechE).

By means of on-campus studying, individuals observe, analyze, and actively contribute to this course of, gaining important insights into the complexities of scaling manufacturing operations. The product of the FrED Manufacturing facility are FrED kits — tabletop manufacturing kits that themselves produce fiber and which are used to show sensible manufacturing ideas. “We’re thrilled to have college students from Monterrey Tec right here at MIT, bringing new concepts and views, and serving to to develop these new methods to show manufacturing at each MIT and Tec,” says Anthony.

The FrED manufacturing unit was initially constructed by a gaggle of MIT graduate college students in 2022 as their thesis mission within the Grasp of Engineering in Superior Manufacturing and Design program. They tailored and scaled the unique design of the machine, constructed by Anthony’s scholar David Kim, into one thing that may very well be manufactured into a number of items at a considerably decrease price. The ensuing computer-aided design recordsdata have been shared with Tec de Monterrey to be used by college and college students. Since launching the FrED curriculum at Tec in 2022, MIT has co-hosted two programs led by Tec college: “Mechatronics Design: (Re) Design of FrED,” and “Automation of Manufacturing Methods: FrED Manufacturing facility Problem.”

New this tutorial yr, undergraduate Tec college students are taking part in FrED Manufacturing facility analysis immersions. The scholars interact in collaborative FrED tasks at MIT after which return to Tec to implement their data — notably to assist replicate and implement what they’ve realized, with the launch of a brand new FrED Manufacturing facility at Tec de Monterrey this spring. The tip purpose is to completely combine this mission into Tec’s mechatronics engineering curriculum, during which college students find out about automation and robotics firsthand by way of the gadgets.

Russel Bradley, a PhD scholar in MechE supervised by Anthony, is the mission lead of FrED Manufacturing facility and has been working carefully with the undergraduate Tec college students.

“The method of designing and manufacturing FrEDs is an academic expertise in itself,” says Bradley. “In contrast to an actual manufacturing unit, which probably wouldn’t welcome college students to experiment with the machines, the FrED manufacturing unit gives an setting the place you may fail and study.”

The Tec undergrads are divided into teams engaged on particular tasks, together with Improvement of an Training 4.0 Framework for FrED, Immersive Expertise (AR) for Manufacturing Operations, Gamifying Superior Manufacturing Training in FrED Manufacturing facility, and Immersive Cognitive Manufacturing facility Twins.

Sergio Siller Lobo is a Tec scholar who’s engaged on the event of the schooling framework for FrED. He and different college students are revising the code to make the interface extra student-friendly and greatest allow the scholars to study whereas working with the gadgets. They’re centered notably on serving to college students to interact with the subjects of management methods, laptop imaginative and prescient, and web of issues (IoT) in each a digital course that they’re growing, and in immediately working with the gadgets. The digital course could be introduced by an teacher or accomplished autonomously by college students.

“College students could be studying the speculation with the digital programs, in addition to gaining access to hands-on, sensible expertise with the machine,” says Siller Lobo. “You may have one of the best of each methods of studying, each the sensible and the theoretical.”

Arik Gómez Horita, an undergrad from Tec who has additionally been engaged on the schooling framework, says that the expertise that presently exists when it comes to how one can educate college students about management methods, laptop imaginative and prescient, and IoT is usually very restricted in both its functionality or amount.

“A key side of the worth of the FrEDs is that we’re integrating all these ideas and a module for schooling right into a single machine,” says Gómez Horita. “Bringing FrED right into a classroom is a game-changer. Our most important purpose is attempting to place FrED into the fingers of the instructor, to make use of it for all its educating capabilities.”

As soon as the scholars return to Tec de Monterrey with the academic modules they’ve developed, there might be workshops with the FrEDs and alternatives for Tec college students to make use of their very own creativity and iterate on the gadgets.

“The FrED is mostly a lab in a field, and the most effective issues that FrEDs do is create information,” says Siller Lobo. “Discovering new methods to get information from FrED offers it extra worth.”

Tec college students Ángel Alarcón and André Mendoza are making ready to have MIT college students take a look at the FrED manufacturing unit, working a simulation with the 2 most important roles of engineer and operator. The operator position assembles the FrEDs inside the workstations that simulate a manufacturing unit. The engineer position analyzes the info created on the manufacturing unit aspect by the operator and tries to search out methods to enhance manufacturing.

“It is a very immersive solution to educate manufacturing methods,” says Alarcón. “Many college students finding out manufacturing, undergraduate and even graduate, end their schooling by no means having even gone to an precise manufacturing unit. The FrED Manufacturing facility offers college students the dear alternative to get to know what a manufacturing unit is like and expertise an trade setting with out having to go off campus.”

The information gained from the workstations — together with cycle time and defects in an operation — might be used to show completely different subjects about manufacturing. Finally, the FrED manufacturing unit at Tec might be used to check the advantages and disadvantages of automation versus guide labor.

Bradley says that the Tec college students carry a powerful mechatronics background that provides a whole lot of vital insights to the mission, and past the lab, it’s additionally a useful multicultural trade.

“It’s not nearly what the scholars are studying from us,” says Bradley, “but it surely’s actually a collaborative course of during which we’re all complementing one another.”