Instructing a robotic new expertise used to require coding experience. However a brand new era of robots may probably be taught from nearly anybody.

Engineers are designing robotic helpers that may “be taught from demonstration.” This extra pure coaching technique permits an individual to guide a robotic via a process, sometimes in one in every of 3 ways: through distant management, reminiscent of working a joystick to remotely maneuver a robotic; by bodily shifting the robotic via the motions; or by performing the duty themselves whereas the robotic watches and mimics.

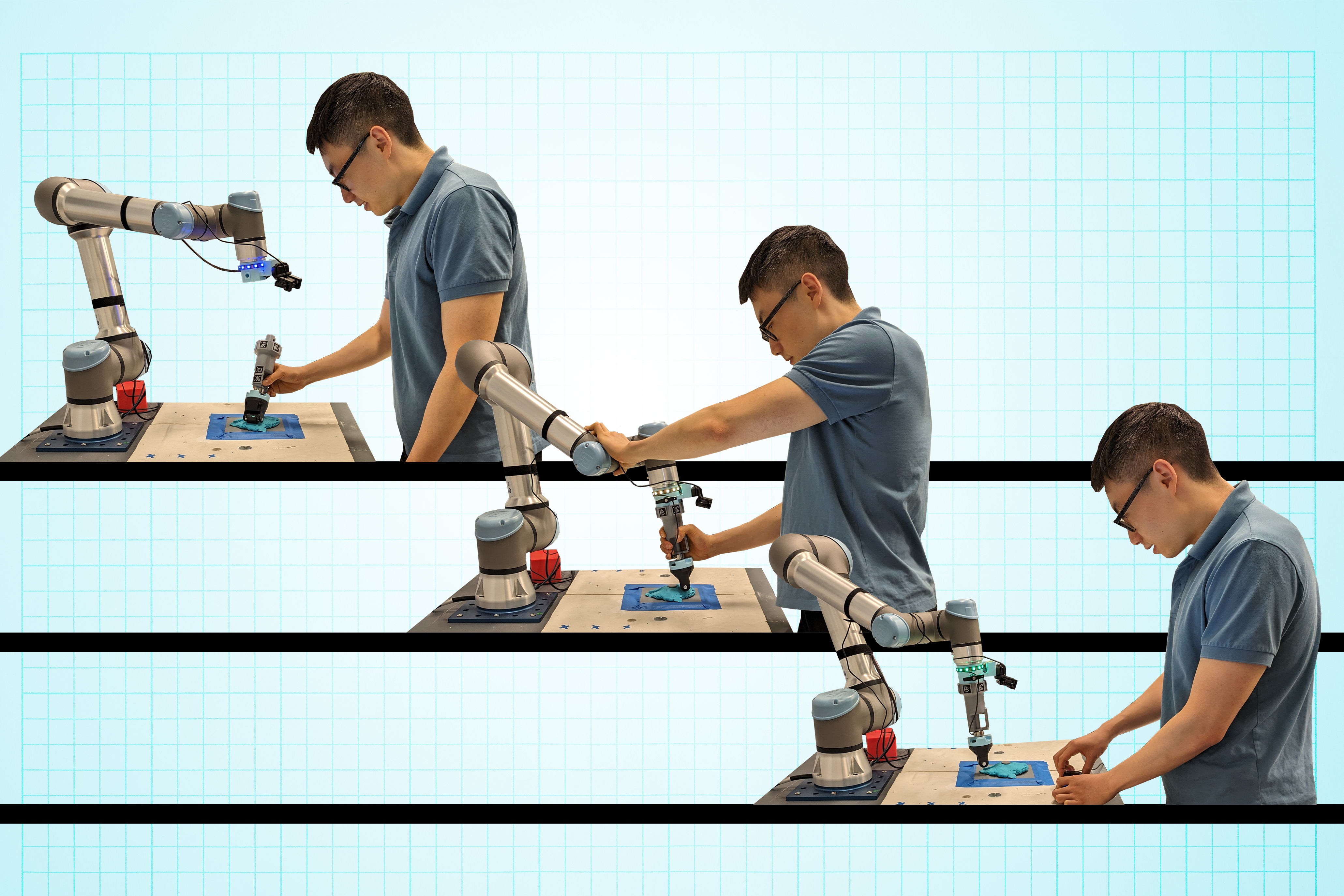

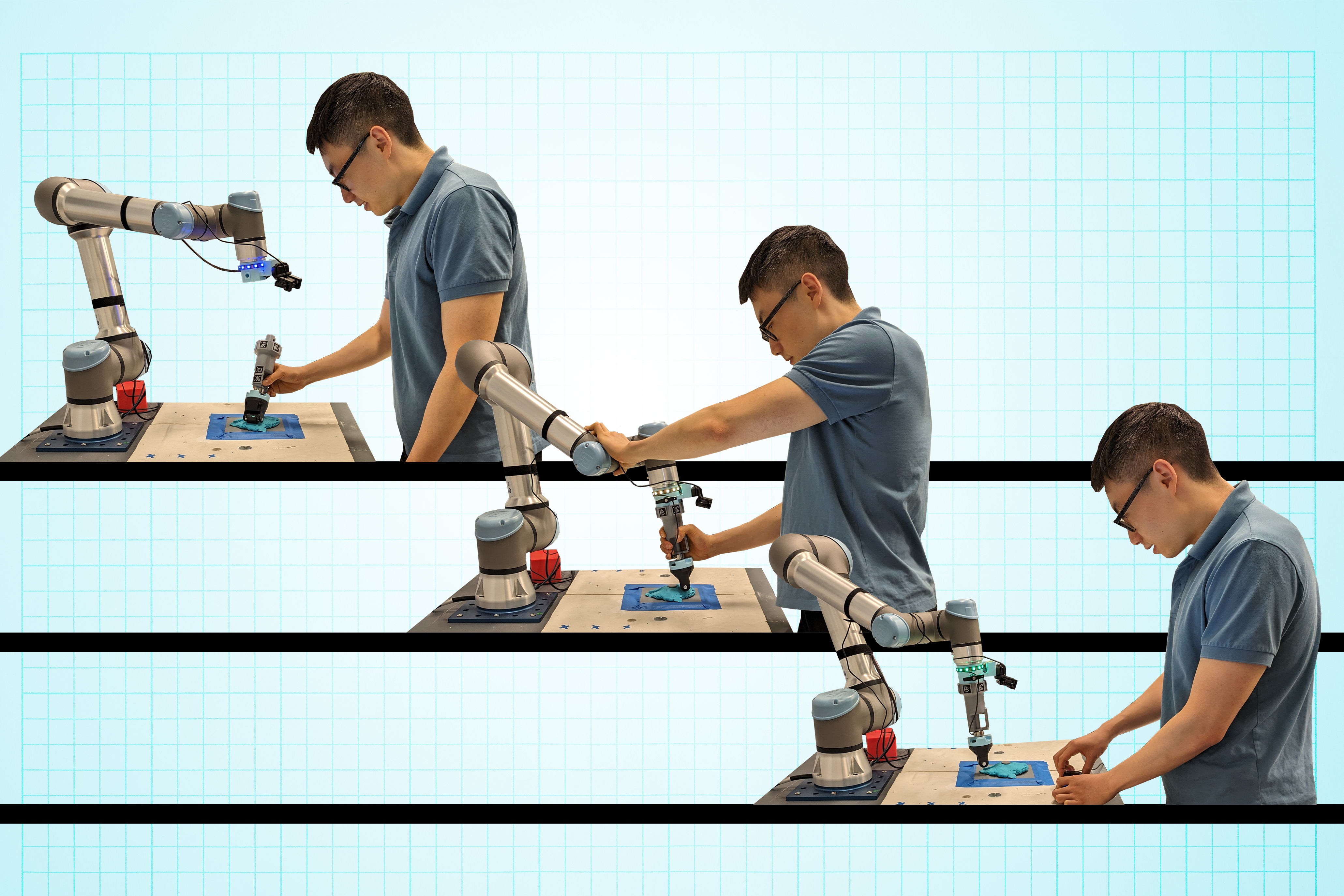

Studying-by-doing robots often practice in simply one in every of these three demonstration approaches. However MIT engineers have now developed a three-in-one coaching interface that permits a robotic to be taught a process via any of the three coaching strategies. The interface is within the type of a handheld, sensor-equipped instrument that may connect to many frequent collaborative robotic arms. An individual can use the attachment to show a robotic to hold out a process by remotely controlling the robotic, bodily manipulating it, or demonstrating the duty themselves — whichever fashion they like or most closely fits the duty at hand.

The MIT group examined the brand new instrument, which they name a “versatile demonstration interface,” on a typical collaborative robotic arm. Volunteers with manufacturing experience used the interface to carry out two handbook duties which can be generally carried out on manufacturing facility flooring.

The researchers say the brand new interface gives elevated coaching flexibility that might develop the kind of customers and “lecturers” who work together with robots. It could additionally allow robots to be taught a wider set of expertise. As an example, an individual may remotely practice a robotic to deal with poisonous substances, whereas additional down the manufacturing line one other individual may bodily transfer the robotic via the motions of boxing up a product, and on the finish of the road, another person may use the attachment to attract an organization emblem because the robotic watches and learns to do the identical.

“We try to create extremely smart and expert teammates that may successfully work with people to get advanced work executed,” says Mike Hagenow, a postdoc at MIT within the Division of Aeronautics and Astronautics. “We consider versatile demonstration instruments can assist far past the manufacturing flooring, in different domains the place we hope to see elevated robotic adoption, reminiscent of house or caregiving settings.”

Hagenow will current a paper detailing the brand new interface, on the IEEE Clever Robots and Programs (IROS) convention in October. The paper’s MIT co-authors are Dimosthenis Kontogiorgos, a postdoc on the MIT Laptop Science and Synthetic Intelligence Lab (CSAIL); Yanwei Wang PhD ’25, who lately earned a doctorate in electrical engineering and pc science; and Julie Shah, MIT professor and head of the Division of Aeronautics and Astronautics.

Coaching collectively

Shah’s group at MIT designs robots that may work alongside people within the office, in hospitals, and at house. A primary focus of her analysis is creating methods that allow folks to show robots new duties or expertise “on the job,” because it had been. Such methods would, as an illustration, assist a manufacturing facility flooring employee shortly and naturally modify a robotic’s maneuvers to enhance its process within the second, somewhat than pausing to reprogram the robotic’s software program from scratch — a talent {that a} employee might not essentially have.

The group’s new work builds on an rising technique in robotic studying referred to as “studying from demonstration,” or LfD, wherein robots are designed to be educated in additional pure, intuitive methods. In trying via the LfD literature, Hagenow and Shah discovered LfD coaching strategies developed to this point fall typically into the three primary classes of teleoperation, kinesthetic coaching, and pure instructing.

One coaching methodology may match higher than the opposite two for a specific individual or process. Shah and Hagenow questioned whether or not they may design a instrument that mixes all three strategies to allow a robotic to be taught extra duties from extra folks.

“If we may deliver collectively these three alternative ways somebody may need to work together with a robotic, it could deliver advantages for various duties and totally different folks,” Hagenow says.

Duties at hand

With that purpose in thoughts, the group engineered a brand new versatile demonstration interface (VDI). The interface is a handheld attachment that may match onto the arm of a typical collaborative robotic arm. The attachment is provided with a digital camera and markers that monitor the instrument’s place and actions over time, together with drive sensors to measure the quantity of strain utilized throughout a given process.

When the interface is hooked up to a robotic, the complete robotic could be managed remotely, and the interface’s digital camera information the robotic’s actions, which the robotic can use as coaching knowledge to be taught the duty by itself. Equally, an individual can bodily transfer the robotic via a process, with the interface hooked up. The VDI can be indifferent and bodily held by an individual to carry out the specified process. The digital camera information the VDI’s motions, which the robotic may also use to imitate the duty when the VBI is reattached.

To check the attachment’s usability, the group introduced the interface, together with a collaborative robotic arm, to a neighborhood innovation middle the place manufacturing consultants find out about and take a look at know-how that may enhance factory-floor processes. The researchers arrange an experiment the place they requested volunteers on the middle to make use of the robotic and all three of the interface’s coaching strategies to finish two frequent manufacturing duties: press-fitting and molding. In press-fitting, the consumer educated the robotic to press and match pegs into holes, just like many fastening duties. For molding, a volunteer educated the robotic to push and roll a rubbery, dough-like substance evenly across the floor of a middle rod, just like some thermomolding duties.

For every of the 2 duties, the volunteers had been requested to make use of every of the three coaching strategies, first teleoperating the robotic utilizing a joystick, then kinesthetically manipulating the robotic, and eventually, detaching the robotic’s attachment and utilizing it to “naturally” carry out the duty because the robotic recorded the attachment’s drive and actions.

The researchers discovered the volunteers typically most well-liked the pure methodology over teleoperation and kinesthetic coaching. The customers, who had been all consultants in manufacturing, did provide eventualities wherein every methodology might need benefits over the others. Teleoperation, as an illustration, could also be preferable in coaching a robotic to deal with hazardous or poisonous substances. Kinesthetic coaching may assist employees modify the positioning of a robotic that’s tasked with shifting heavy packages. And pure instructing could possibly be helpful in demonstrating duties that contain delicate and exact maneuvers.

“We think about utilizing our demonstration interface in versatile manufacturing environments the place one robotic may help throughout a spread of duties that profit from particular forms of demonstrations,” says Hagenow, who plans to refine the attachment’s design primarily based on consumer suggestions and can use the brand new design to check robotic studying. “We view this examine as demonstrating how larger flexibility in collaborative robots could be achieved via interfaces that develop the ways in which end-users work together with robots throughout instructing.”

This work was supported, partly, by the MIT Postdoctoral Fellowship Program for Engineering Excellence and the Wallenberg Basis Postdoctoral Analysis Fellowship.

Instructing a robotic new expertise used to require coding experience. However a brand new era of robots may probably be taught from nearly anybody.

Engineers are designing robotic helpers that may “be taught from demonstration.” This extra pure coaching technique permits an individual to guide a robotic via a process, sometimes in one in every of 3 ways: through distant management, reminiscent of working a joystick to remotely maneuver a robotic; by bodily shifting the robotic via the motions; or by performing the duty themselves whereas the robotic watches and mimics.

Studying-by-doing robots often practice in simply one in every of these three demonstration approaches. However MIT engineers have now developed a three-in-one coaching interface that permits a robotic to be taught a process via any of the three coaching strategies. The interface is within the type of a handheld, sensor-equipped instrument that may connect to many frequent collaborative robotic arms. An individual can use the attachment to show a robotic to hold out a process by remotely controlling the robotic, bodily manipulating it, or demonstrating the duty themselves — whichever fashion they like or most closely fits the duty at hand.

The MIT group examined the brand new instrument, which they name a “versatile demonstration interface,” on a typical collaborative robotic arm. Volunteers with manufacturing experience used the interface to carry out two handbook duties which can be generally carried out on manufacturing facility flooring.

The researchers say the brand new interface gives elevated coaching flexibility that might develop the kind of customers and “lecturers” who work together with robots. It could additionally allow robots to be taught a wider set of expertise. As an example, an individual may remotely practice a robotic to deal with poisonous substances, whereas additional down the manufacturing line one other individual may bodily transfer the robotic via the motions of boxing up a product, and on the finish of the road, another person may use the attachment to attract an organization emblem because the robotic watches and learns to do the identical.

“We try to create extremely smart and expert teammates that may successfully work with people to get advanced work executed,” says Mike Hagenow, a postdoc at MIT within the Division of Aeronautics and Astronautics. “We consider versatile demonstration instruments can assist far past the manufacturing flooring, in different domains the place we hope to see elevated robotic adoption, reminiscent of house or caregiving settings.”

Hagenow will current a paper detailing the brand new interface, on the IEEE Clever Robots and Programs (IROS) convention in October. The paper’s MIT co-authors are Dimosthenis Kontogiorgos, a postdoc on the MIT Laptop Science and Synthetic Intelligence Lab (CSAIL); Yanwei Wang PhD ’25, who lately earned a doctorate in electrical engineering and pc science; and Julie Shah, MIT professor and head of the Division of Aeronautics and Astronautics.

Coaching collectively

Shah’s group at MIT designs robots that may work alongside people within the office, in hospitals, and at house. A primary focus of her analysis is creating methods that allow folks to show robots new duties or expertise “on the job,” because it had been. Such methods would, as an illustration, assist a manufacturing facility flooring employee shortly and naturally modify a robotic’s maneuvers to enhance its process within the second, somewhat than pausing to reprogram the robotic’s software program from scratch — a talent {that a} employee might not essentially have.

The group’s new work builds on an rising technique in robotic studying referred to as “studying from demonstration,” or LfD, wherein robots are designed to be educated in additional pure, intuitive methods. In trying via the LfD literature, Hagenow and Shah discovered LfD coaching strategies developed to this point fall typically into the three primary classes of teleoperation, kinesthetic coaching, and pure instructing.

One coaching methodology may match higher than the opposite two for a specific individual or process. Shah and Hagenow questioned whether or not they may design a instrument that mixes all three strategies to allow a robotic to be taught extra duties from extra folks.

“If we may deliver collectively these three alternative ways somebody may need to work together with a robotic, it could deliver advantages for various duties and totally different folks,” Hagenow says.

Duties at hand

With that purpose in thoughts, the group engineered a brand new versatile demonstration interface (VDI). The interface is a handheld attachment that may match onto the arm of a typical collaborative robotic arm. The attachment is provided with a digital camera and markers that monitor the instrument’s place and actions over time, together with drive sensors to measure the quantity of strain utilized throughout a given process.

When the interface is hooked up to a robotic, the complete robotic could be managed remotely, and the interface’s digital camera information the robotic’s actions, which the robotic can use as coaching knowledge to be taught the duty by itself. Equally, an individual can bodily transfer the robotic via a process, with the interface hooked up. The VDI can be indifferent and bodily held by an individual to carry out the specified process. The digital camera information the VDI’s motions, which the robotic may also use to imitate the duty when the VBI is reattached.

To check the attachment’s usability, the group introduced the interface, together with a collaborative robotic arm, to a neighborhood innovation middle the place manufacturing consultants find out about and take a look at know-how that may enhance factory-floor processes. The researchers arrange an experiment the place they requested volunteers on the middle to make use of the robotic and all three of the interface’s coaching strategies to finish two frequent manufacturing duties: press-fitting and molding. In press-fitting, the consumer educated the robotic to press and match pegs into holes, just like many fastening duties. For molding, a volunteer educated the robotic to push and roll a rubbery, dough-like substance evenly across the floor of a middle rod, just like some thermomolding duties.

For every of the 2 duties, the volunteers had been requested to make use of every of the three coaching strategies, first teleoperating the robotic utilizing a joystick, then kinesthetically manipulating the robotic, and eventually, detaching the robotic’s attachment and utilizing it to “naturally” carry out the duty because the robotic recorded the attachment’s drive and actions.

The researchers discovered the volunteers typically most well-liked the pure methodology over teleoperation and kinesthetic coaching. The customers, who had been all consultants in manufacturing, did provide eventualities wherein every methodology might need benefits over the others. Teleoperation, as an illustration, could also be preferable in coaching a robotic to deal with hazardous or poisonous substances. Kinesthetic coaching may assist employees modify the positioning of a robotic that’s tasked with shifting heavy packages. And pure instructing could possibly be helpful in demonstrating duties that contain delicate and exact maneuvers.

“We think about utilizing our demonstration interface in versatile manufacturing environments the place one robotic may help throughout a spread of duties that profit from particular forms of demonstrations,” says Hagenow, who plans to refine the attachment’s design primarily based on consumer suggestions and can use the brand new design to check robotic studying. “We view this examine as demonstrating how larger flexibility in collaborative robots could be achieved via interfaces that develop the ways in which end-users work together with robots throughout instructing.”

This work was supported, partly, by the MIT Postdoctoral Fellowship Program for Engineering Excellence and the Wallenberg Basis Postdoctoral Analysis Fellowship.